High quality and hot sale 1500V thin film junction box PV-BN221

Description

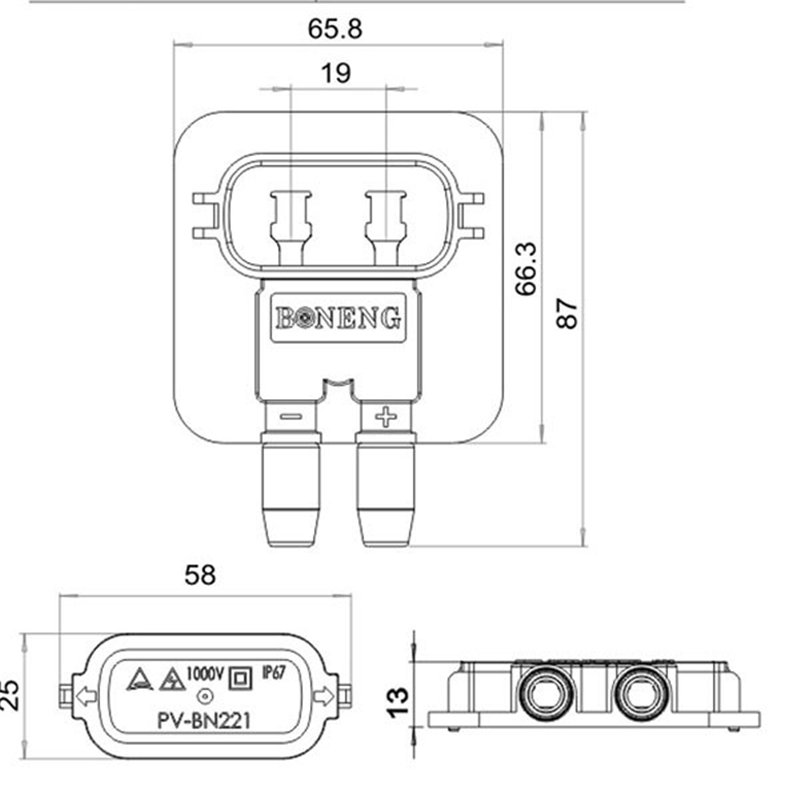

This solar junction box is fully potting-glue, waterproof, outdoor design and certified by TUV. It has excellent performance of high temperature resistance, fire resistance, aging resistance and ultraviolet resistance, which can meet the long-term use under outdoor harsh environmental conditions. Small shape, ultra-thin design, simple and practical structure, and suitable for 90W crystal silicon photovoltaic module or thin film photovoltaic module. The connection of the bus bar and the cable is welded and crimp respectively. The electrical performance is safe and reliable. Suitable for cadmium telluride, copper indium gallium selenium, perovskite, amorphous thin film batteries. This type of thin film junction box is suitable for the module back connection process, which can reduce the power consumption of photovoltaic modules and improve electrical reliability.

Technical Support

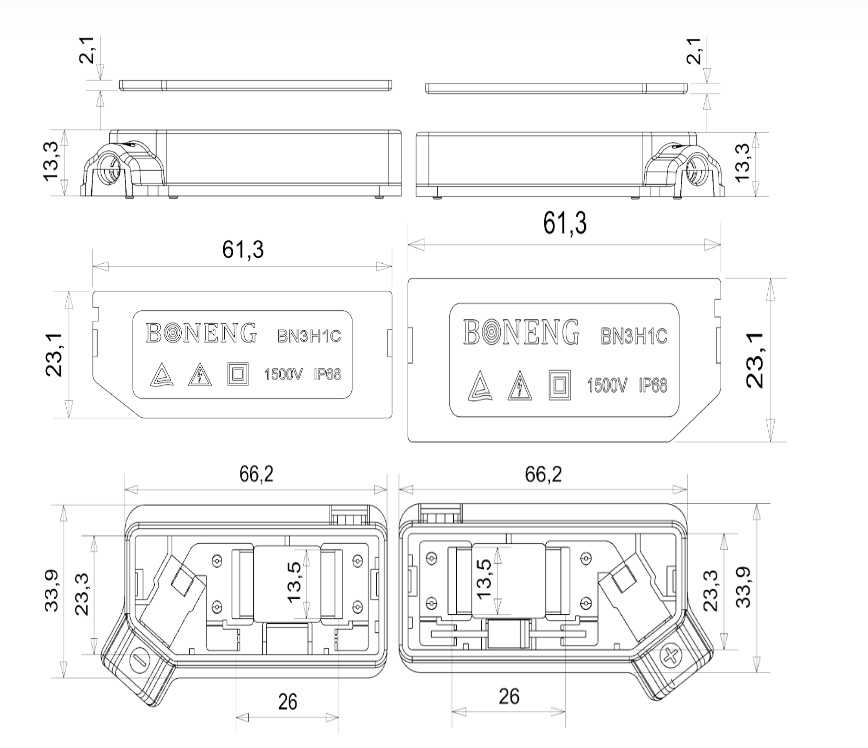

| Rated voltage | 1000V | Flame Class | UL94-V0 (TUV)/5VA(UL) |

| Rated current | 4.8A-10A | Cable Specifications | 1.5-4mm2 |

| Operating temperature | -40°C-+85°C(TUV)/-40°C-+90°C(UL) | Waterproof Structure | Potting |

| Safety class | Class II | Waterproof rating | IP68 |

| Application level | Class A | Potting Glue quantity | 7g |

| Maximum bus bar width | 13. 5mm | Busbar connect ion | Soldering |

| Insulation Material | PPE | Contact Material | Copper, Tin-Plated |

Product Configuration List

| Diode Rated Voltage | 20A |

| Diode Type | 10A10 |

| Diode Qty | 1 |

Application

Unshielded solar panels for thin film batteries to improve solar energy

Solution

● The JB mounting hole of the terminal base must line up with the ribbon of the PV module.

● Compound for sealing and adhering Applying potting glue requires a precise kind and specification. Make certain JB will be fixed in the appropriate location with a trustworthy sealant. Diodes and the terminal base's top surface should be covered in potting glue. to reduce the risk of electrical shock.

● Avoid moving the PV module or JB until the potting glue, adhesive, and sealing compound have fully hardened.

● To prevent missing or erroneous soldering, make sure the connection between the Ribbons and terminal is reliably soldered. The soldering operators need to have formal training. The diodes will become damaged with more soldering time.

● Use anti-static protection techniques when handling or soldering JB.

● Ensure that the PV module and JB are connected using the proper polarity. If not, the incorrect connection will start a fire.

● Before shipping, the diodes of JBs should be examined by the PV module manufacturer because they may be harmed by heat or static shock.

● Professional specialists should do any installation or maintenance.

● Make sure connectors are disconnected from the power source while being assembled or disassembled to prevent electric shock.

● Under a load, avoid connecting or disconnecting.

● Keep corrosive materials away from the connector while it is being assembled.

Why Choose Us

We are a direct manufacturer, we can provide customers with customized, high quality, competitive price products. We have a good reputation among our peers and customers. At the same time we have more perfect after-sales service, to solve everything for customers.

Installation Instruction

1.Get a junction box and its base by a clean soft cloth with alcohol.

2.Panel back-sheet Upon, dry, no oil and other dirty. Clean the back-sheet area by a

clean soft cloth with alcohol.

3.Stroke straight the rubber by a pincers,keep vertical against the back-sheet.

4.Get a bottle silicon, cut the mouth of the bottle, making sure the diameter is 4mm, insert it into the air gun, screw cover, no cut on mouth of the air gun.

5.Put the junction box on working desk, get the air gun and keep vertical against the junction box base, gluing around the junction box base edge circle.

6.Get the rubber through the junction box base hole, press hardly the junction box on the back-sheet till the silicon overflow around.

7.Place panels across in the air currents 10 hours till the silicon cures.

8.Check the reliability of each terminal connection, and press the raised bus bar on the connection terminal by hand.

9.Cover the junction box with a click sound, the should not be pick out by hands.

FAQ

Vedio